At Unijoy Manufacturing, a leading swimwear manufacturer in China, we believe true quality means solving problems before they reach your customers. Recently, we faced a challenge that perfectly illustrates our commitment.

The Challenge: When “Good Enough” Wasn’t Enough

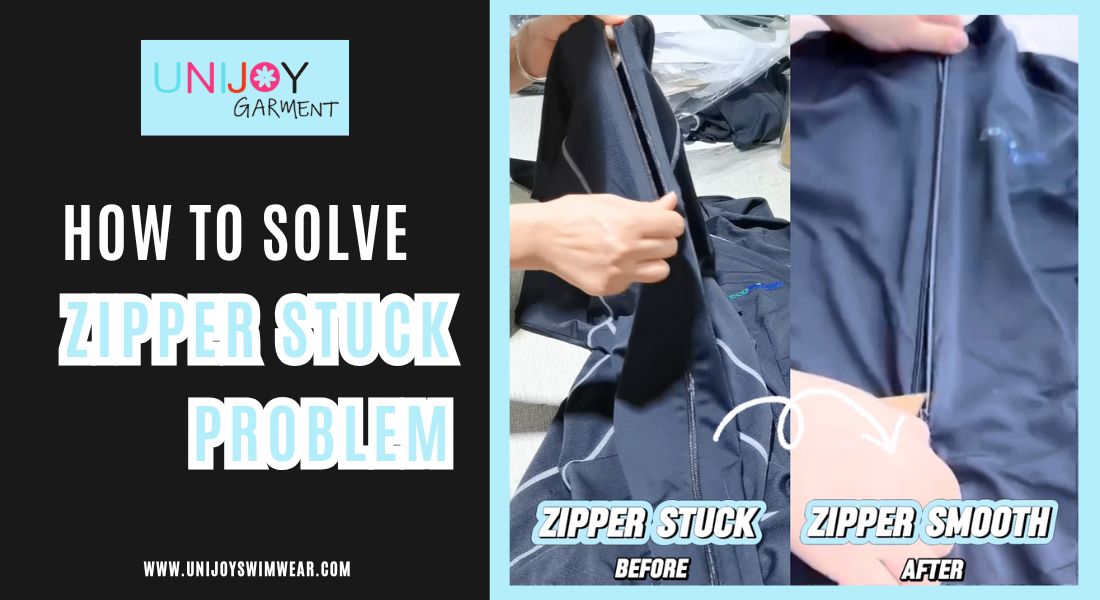

During a final inspection of a bulk swimwear order featuring hidden zippers (requested for superior aesthetics), our quality team discovered an intermittent issue: occasionally, the zipper would snag on the swimwear soft inner fabric when pulled. Though minor, sporadic and potentially unnoticeable to most customers, we refused to ignore it – because your brand reputation matters.

Why Standard Solutions Failed

Our swimwear production team initially suggested two approaches:

Plan A: Doing nothing, as most customers may never encounter the issue.

Plan B: Fully removing and resewing each zipper – a 20-minute-per-garment process that would delay delivery and increase extra costs significantly.

Neither option met our standards as your responsible manufacturing partner.

Our Problem-Solving Journey:

First, we tried ironing fusible interfacing behind the fabric to stiffen it. This worked temporarily, but we discovered the heat required could melt delicate zipper teeth – creating a bigger problem. It was rejected.

Then, we developed our breakthrough solution:

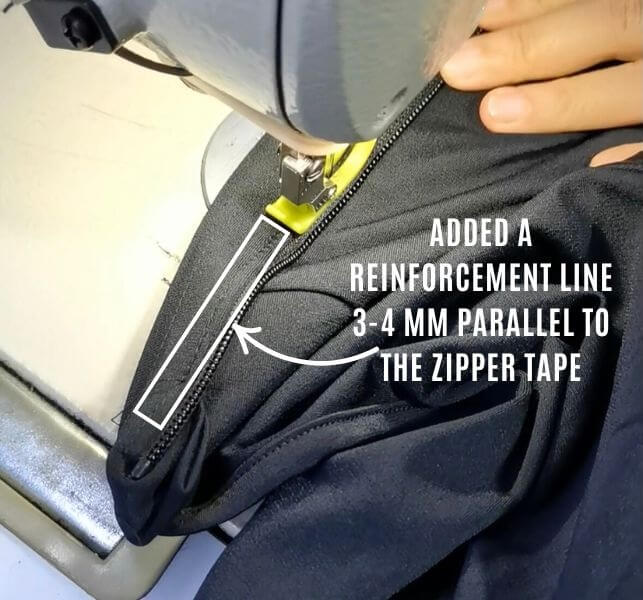

We added a single reinforcement stitch line – precisely placed 3-4mm parallel to the zipper tape.

This simple adjustment achieved two critical improvements:

- It created a tiny protective gap between the zipper teeth and fabric.

- It gently stiffened the surrounding material without adding bulk.

Results for Your Swimwear Business:

- 100% elimination of final bulk swimwear zipper snags

- 80% cost reduction compared to full rework

- Took only 1 minute per swimsuit rework

- Contained quality risk before shipment

- Delivery On time, no delays to our client

When we shared the solution, our client called it “smart work that protects our brand.”

Why This Matters for Your Swimwear Line:

As your reliable swimwear manufacturing partner, we engineered out risks that could impact you:

- Customer returns from quality failures and frustrated shoppers

- Unexpected costs from expensive late-stage fixes

- Production delays that impact your launch plans

Our Quality Promise to Every Partner:

“Most factories fix flaws – we engineer them out permanently.”

When you choose Unijoy Manufacturing as your China swimwear factory, you gain:

- Preventive quality engineering: We simulate real-world wear during prototyping

- Zero-compromise mindset: No “minor” issue is overlooked

- Agile problem-solving: A dedicated technical team resolves challenges within 24 hours

- Brand-first partnership: Your business success drives our process

“After 12 years as a premium swimwear manufacturer in China, we know your trust is earned through relentless attention to detail – not promises.”

Ready to experience stress-free custom swimwear production?

[Contact Us] to engineer quality into your next collection!